Model NO.: Pipe Thread Tap

Chamfer Type: C3 (3–5 threads)

Flute Type: Straight Flute

Coating: TiCN/TiN/No Coating

Limit: 6h

Flute: 3

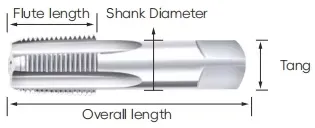

Overall Length: 67 mm

Flute Length: 19 mm

Shank Diameter: 11 mm

K: 9 mm

Dk: 11.7 mm

Specification: G1/4–19

Pipe thread tap

High-Sealing Capability:

Tapered threads create metal-to-metal sealing (NPT/NPTF) or thread+sealant sealing (BSPT), critical for fluid/gas containment.

High Torque Resistance:

Reinforced shank and core resist deformation during high-speed, high-pressure operations.

Reinforced Cutting Structure:

Spiral or straight flute designs optimize chip evacuation in sticky materials (e.g., stainless steel, brass).

Corrosion Protection:

Stainless steel taps (Grade 303/304) resist rust in marine, chemical, or sanitary environments.

High-Speed Machining:

Suitable for CNC machines and automatic lathes at speeds up to 15 m/min.

Thread Quality:

Ground Thread Profile: Achieves 6H tolerance class for critical applications.

TYPICAL APPLICATION SCENARIOS

1. Hydraulic & Pneumatic Systems

Threading NPT/BSPP fittings for pumps, valves, and cylinders (e.g., 3000+ psi hydraulic lines).

2. Oil & Gas Pipeline Connections

Repairing API 5CT casing pipes or installing wellhead NPTF dryseal fittings to prevent leaks.

3. Plumbing & HVAC Installations

Cutting threads on water/gas pipes (BSPT in EU/Asia) or refrigerant lines (NPT in North America).

4. High-Pressure Fluid Transfer

Manufacturing fuel injection lines (automotive) or chemical transfer manifolds (requires NPTF leak-proof threads).

5. Industrial Machinery Maintenance

Re-threading damaged ports on compressors, boilers, or CNC cooling systems.

6 .Marine & Offshore Equipment

Corrosion-resistant taps for seawater piping (BSPP) or ship hydraulic systems (Stainless Steel BSPT).

|

|

| Size | L | Lc | Limit | d | k | dk |

| G1/8-28 | 59 | 15 | 6H | 8 | 6.2 | 8.7 |

| G1/4-19 | 67 | 19 | 6H | 11 | 9 | 11.7 |

| G3/8-19 | 75 | 21 | 6H | 14 | 12 | 15.2 |

| G1/2-14 | 87 | 26 | 6H | 18 | 14.5 | 19 |

| G3/4-14 | 96 | 28 | 6H | 22 | 18 | 24.5 |

| G1-11 | 109 | 33 | 6H | 26 | 22 | 30.2 |

| ZG1/8-28 | 59 | 15 | 6H | 8 | 6.2 | 8.4 |

| ZG1/4-19 | 67 | 19 | 6H | 11 | 9 | 11.2 |

| ZG3/8-19 | 75 | 21 | 6H | 14 | 12 | 14.75 |

| ZG1/2-14 | 87 | 26 | 6H | 18 | 14.5 | 18.25 |

| ZG3/4-14 | 96 | 28 | 6H | 22 | 18 | 23.75 |

| ZG1-11 | 109 | 33 | 6H | 26 | 22 | 30 |

Hegong specializes in high-quality threading tools, including machine taps, hand taps, straight flute taps, spiral flute taps, spiral point taps, and forming thread taps, serving global markets with precision and reliability.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.